Tray cable is a durable, multi-conductor cable designed for power and control applications in industrial, commercial, and utility settings. It is typically installed in cable trays, conduit, ducts, troughs, or wire raceways, and is valued for its versatility and compliance with demanding safety codes.

Multi/Cable’s multi-conductor tray cables are engineered for wet, dry, and hazardous locations, meeting NEC Class I, Division 2 standards for hazardous industrial environments. We offer a variety of insulation and jacketing types, with options rated for direct burial, sunlight resistance, oil resistance, and open wiring (TC-ER) out of tray without conduit.

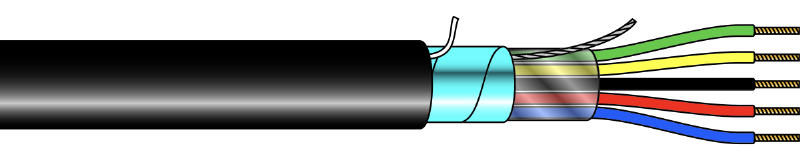

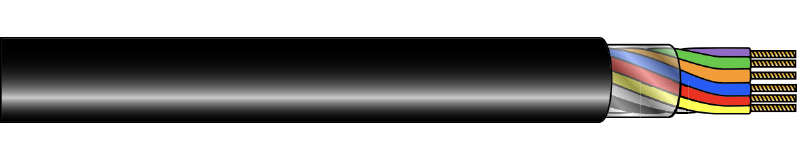

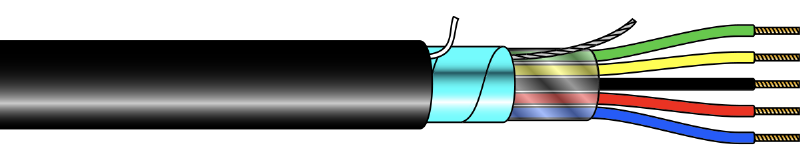

Popular Tray Cable Constructions

PLTC – Power Limited Tray Cable (105ºC, 300V)

Ideal for control circuits and instrumentation systems, PLTC cables reduce electrical interference for sensitive electronics. This industrial tray cable is commonly used in automation, process control, and signal wiring. Approved for Class I, Division 2 hazardous locations.

VNTC – Vinyl/Nylon Tray Cable (90ºC Dry / 75ºC Wet, 600V)

With PVC/nylon-insulated conductors and a flame-retardant PVC jacket, VNTC is a sunlight resistant tray cable approved for Class I remote control and signaling circuits. Suitable for both indoor and outdoor power and control tray cable installations. Engineered to withstand prolonged sunlight exposure, resist oil and a variety of industrial chemicals, and approved for direct burial and TC-ER installations outside of the tray without conduit.

WTTC – Wind Turbine Tray Cable (90ºC, 1000V)

Designed for the extreme conditions of wind energy applications, WTTC cables offer superior resistance to oil, sunlight, vibration, and temperature fluctuations. Built to perform in demanding environments like wind turbine installations, this cable offers exceptional resistance to oil, UV exposure, and a wide range of environmental challenges.

Selecting the Right Tray Cable

Choosing the right multi-conductor tray cable involves matching your project’s voltage and temperature ratings, installation method, and environmental challenges. As a trusted tray cable manufacturer, Multi/Cable helps customers specify the exact tray cable for optimal safety, compliance, and performance — whether it’s a direct burial tray cable for a utility project or a tray cable for hazardous locations in a manufacturing facility.

Request a quote today and tell us about your wire and cable needs. We’ll get back to you within one business day with a quote!

FAQs

What is tray cable used for?

Tray cable is a durable multi-conductor cable designed for distributing power, control signals, and instrumentation wiring in industrial, commercial, and utility environments. Common installations include cable trays, conduits, ducts, and raceways, where reliability and compliance with NEC safety codes are essential. Multi/Cable manufactures custom tray cables for specialized projects, including direct burial tray cable, oil- and sunlight-resistant tray cable, and tray cable for hazardous locations.

What does TC-ER mean?

TC-ER stands for Tray Cable – Exposed Run. A TC-ER cable is approved by the NEC to run outside of a tray without the need for additional conduit protection, as long as it meets specific routing and mechanical protection requirements. This makes TC-ER cables highly versatile and cost-effective in industrial settings. Multi/Cable offers TC-ER rated tray cables in custom constructions to meet the needs of manufacturing plants, utilities, and control systems across Connecticut and nationwide.

Can tray cable be used outdoors?

Yes. Many tray cables are engineered for indoor and outdoor applications, with jacketing materials that provide sunlight resistance, moisture resistance, and oil resistance. For example, Multi/Cable’s VNTC (Vinyl/Nylon Tray Cable) is sunlight resistant, approved for direct burial, and designed to perform in exposed environments. If your project requires custom outdoor tray cable, we can manufacture a solution optimized for UV protection, temperature fluctuations, and long-term durability.

What are the different types of tray cable?

There are several tray cable constructions, each designed for unique applications:

PLTC (Power Limited Tray Cable) – Ideal for control circuits, instrumentation, and sensitive electronics.

VNTC (Vinyl/Nylon Tray Cable) – A rugged 600V option suitable for indoor/outdoor use, resistant to oil, chemicals, and sunlight.

WTTC (Wind Turbine Tray Cable) – Designed for wind energy applications with resistance to vibration, oil, and UV exposure.

As a custom tray cable manufacturer, Multi/Cable can build variations of each construction to match your exact project requirements.

What is the difference between PLTC and VNTC tray cable?

PLTC (Power Limited Tray Cable) is a 300V cable used for instrumentation and low-voltage control circuits. It helps minimize electrical interference and is NEC-approved for hazardous locations.

VNTC (Vinyl/Nylon Tray Cable) is a 600V cable with PVC/nylon-insulated conductors and a durable jacket for indoor/outdoor power and control applications.

Both options are available as custom tray cables, ensuring the right balance of performance, compliance, and durability.

Can tray cable be directly buried?

Yes, certain tray cables are rated for direct burial when they use specific jacketing materials that protect against moisture, soil conditions, and chemical exposure. Multi/Cable manufactures direct burial tray cables for utilities, solar installations, and industrial projects, ensuring long-lasting performance underground.

Where is tray cable required by code?

Tray cable is required in many industrial and commercial projects where wiring must comply with NEC Article 336. Applications include cable trays, raceways, ducts, and hazardous environments (Class I, Division 2). Multi/Cable engineers tray cables that meet NEC requirements while offering custom construction options for Connecticut businesses and nationwide clients.

Why choose Multi/Cable as your tray cable manufacturer?

Multi/Cable has over 40 years of experience as a leading custom tray cable manufacturer. We produce multi-conductor tray cables designed for industrial control, power distribution, and hazardous locations. Every cable is engineered for performance, compliance, and long service life, with fast turnaround times and personalized support.

Choosing a Conductor for your cable

Choosing a Conductor for your cable Choosing Insulation and Jacketing Materials for your Custom Cable

Choosing Insulation and Jacketing Materials for your Custom Cable The Complete Thermocouple Wire & Cable Guide

The Complete Thermocouple Wire & Cable Guide